This site uses cookies to maintain login information on FarmallCub.Com. Click the X in the banner upper right corner to close this notice. For more information on our privacy policy, visit this link: Privacy Policy

NEW REGISTERED MEMBERS: Be sure to check your SPAM/JUNK folders for the activation email.

PVC pipe on snow plow blade?

Forum rules

Notice: For sale and wanted posts are not allowed in this forum. Please use our free classifieds or one of our site sponsors for your tractor and parts needs.

Notice: For sale and wanted posts are not allowed in this forum. Please use our free classifieds or one of our site sponsors for your tractor and parts needs.

- cjpenny89

- 10+ Years

- Posts: 1080

- Joined: Mon Feb 03, 2003 1:15 pm

- Location: St. Charles, MI 48655

PVC pipe on snow plow blade?

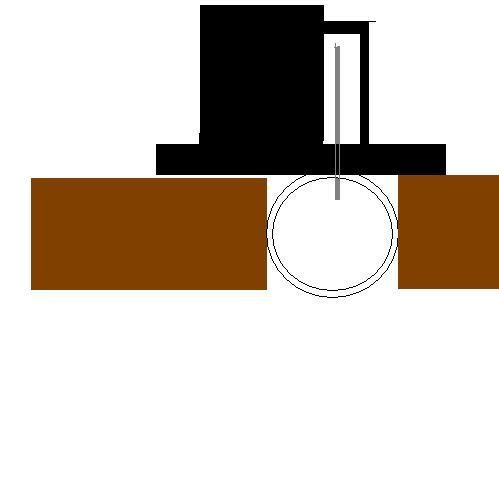

I seem to recall last year some guys were doing this? Some how taking a piece of 2" PVC pipe and some how cutting it down the center and taking it and slipping it over there snow blade so it didn't cut into the Gravel or tear up the black top?

If anyone has any info on this please explane how you do it and how you cut the PVS pipe and how you attach it to the tractor.

Thanks

Chad

oh and how good does it work?

If anyone has any info on this please explane how you do it and how you cut the PVS pipe and how you attach it to the tractor.

Thanks

Chad

oh and how good does it work?

- Rudi

- Cub Pro

- Posts: 28706

- Joined: Sun Feb 02, 2003 8:37 pm

- Zip Code: E1A7J3

- Skype Name: R.H. "Rudi" Saueracker, SSM

- Tractors Owned: 1947 Cub "Granny"

1948 Cub "Ellie-Mae"

1968 Cub Lo-Boy

Dad's Putt-Putt

IH 129 CC

McCormick 100 Manure Spreader

McCormick 100-H Manure Spreader

Post Hole Digger

M-H #1 Potato Digger - Circle of Safety: Y

- Twitter ID: Rudi Saueracker, SSM

- Location: NB Dieppe, Canada

- Contact:

Chad:

I haven't made any specifically for the Cub-54 series blades, but the procedure would be pretty simple and pretty much the same as making roller guards and stuff from PVC for use in the shop.

I haven't made any specifically for the Cub-54 series blades, but the procedure would be pretty simple and pretty much the same as making roller guards and stuff from PVC for use in the shop.

Do ensure that you pay close attention to safe practices. Each of us do things differently, so I won't get into too much detail. When my wife watches me work.. she almost has a coronary.. so I try to make sure that she doesn't

she almost has a coronary.. so I try to make sure that she doesn't  see me when I do the complicated stuff. After over 40 years of playing with this stuff.. and having safety ingrained (yes, accidents still happen.. and NO DON't ASK), you almost unconsciously know what to do. How to explain it is a totally different critter.

see me when I do the complicated stuff. After over 40 years of playing with this stuff.. and having safety ingrained (yes, accidents still happen.. and NO DON't ASK), you almost unconsciously know what to do. How to explain it is a totally different critter.

I haven't made any specifically for the Cub-54 series blades, but the procedure would be pretty simple and pretty much the same as making roller guards and stuff from PVC for use in the shop.

I haven't made any specifically for the Cub-54 series blades, but the procedure would be pretty simple and pretty much the same as making roller guards and stuff from PVC for use in the shop.

- 1. You need a table saw with a good fence.

2. Determine the max thickness of the blade on the snow plow.

3. Carefully set the fence so that two identical cuts can be made from one cheek then the other so that when the PVC slot is finished it is oh I would say about 1/16" less than the thickness of the blade. This will allow for gripping pressure against the steel.

4. Set the blade height to JUST clear the inside of the PVC by 1/32" or so.. not much. Just enough to cool and make a clean cut.

5. Very carefully, but so as to not melt the PVC on your blade, make the required cuts. It would be helpful to have featherboards or a guide to prevent some roll-around as you are cutting the pipe.

Do ensure that you pay close attention to safe practices. Each of us do things differently, so I won't get into too much detail. When my wife watches me work..

she almost has a coronary.. so I try to make sure that she doesn't

she almost has a coronary.. so I try to make sure that she doesn't  see me when I do the complicated stuff. After over 40 years of playing with this stuff.. and having safety ingrained (yes, accidents still happen.. and NO DON't ASK), you almost unconsciously know what to do. How to explain it is a totally different critter.

see me when I do the complicated stuff. After over 40 years of playing with this stuff.. and having safety ingrained (yes, accidents still happen.. and NO DON't ASK), you almost unconsciously know what to do. How to explain it is a totally different critter.Confusion breeds Discussion which breeds Knowledge which breeds Confidence which breeds Friendship

- kinelbor

- 10+ Years

- Posts: 1132

- Joined: Sun May 29, 2005 1:21 pm

- Zip Code: 04762

- Location: ME, New Sweden

- Contact:

Be very careful cutting a round pipe on a table saw. I am in residention construction at college, and that was one thing that we learned you should NEVER cut anything round with a table saw. I think it would be easier and safer to clamp the pipe between board the same thickness of the pipe and just run down it with a skill saw, roll few degrees for next cut and reclamp.

Nik - 1948 Farmall Cub

- Rudi

- Cub Pro

- Posts: 28706

- Joined: Sun Feb 02, 2003 8:37 pm

- Zip Code: E1A7J3

- Skype Name: R.H. "Rudi" Saueracker, SSM

- Tractors Owned: 1947 Cub "Granny"

1948 Cub "Ellie-Mae"

1968 Cub Lo-Boy

Dad's Putt-Putt

IH 129 CC

McCormick 100 Manure Spreader

McCormick 100-H Manure Spreader

Post Hole Digger

M-H #1 Potato Digger - Circle of Safety: Y

- Twitter ID: Rudi Saueracker, SSM

- Location: NB Dieppe, Canada

- Contact:

Nik:

Normally I would just send you a PM about this or on MSN, but this is just too important not to discuss here and now.

I might agree somewhat with your instructors on that point if life was simple and all shops/home workshops could have access to specifically designed tools. On the surface at first blush it seems sound. But it is flawed - dangerously flawed logic. They need to re-evaluate what they are teaching you. And for God's Sake -- NIK -- please please please do not do that!

It is similar Young Drivers telling a young driving student (I have had 2 take the course), that you must stop at least a car length away from a traffic light in case somebody turns too sharply, and you can then avoid an accident. The problem with that is that it is impractical. What happens if you are the first vehicle at the light, you do as taught by YD and you sit there for ever, because you are 20 feet or so AWAY from the sensor that activates the light... .

.

There are many things in life that one does because that is the way to do it.

I did a bit of searching and remembering that Shop Notes actually does stuff like this. I went looking, and poof, here is an article on how to safely do exactly that.. cut a slot in PVC piping on Table Saw safely. This is published, so the liability issue is taken care of I imagine. Right click on the link and choose save as, as it is a pdf file Mobile Planer Stand.

As for the circular saw suggestion.. that is the most scary thought going. That is the most dangerous use of a skill saw that I have ever heard. Your instructor needs to take a safety course. Been there, done that.. improvisation can get somebody seriously hurt.... ask my neighbour Bernie G. who has been a carpenter for almost 40 years himself. 5 years ago he improvised and used a circular/skill saw instead of taking the time to setup properly on his portable table saw and promptly cut off 2 fingers.

promptly cut off 2 fingers.

It was in the newspapers.. cops were out looking for a missing body. Some woman found his finger in her back yard.. 50 feet and across a 6 foot high fence from where he was working. Kind of embarassing for the cops when they figured it all out, but not as embarassing as it was for Bernie or less painful. He still works at his trade, but they were not able to save either finger....

Use the right tool, the right jigs, clamps, hold downs required to perform the needed operation safely. I have seen way too many of my carpenter friends and cabinet maker friends cutting off important parts of their body. After 52 years of life, I still have all of my parts.. well pretty much intact after over 40 + years playing with hand and power tools.

Ask your instructors how to cut a cove moulding on a table saw, dowels, cabriole legs, ? Or a myriad of other tasks that in our so-called intelligent society we now have machines to do so with. I am trying to figure out how many home owners can afford nevermind understand how to use a stick moulder

Normally I would just send you a PM about this or on MSN, but this is just too important not to discuss here and now.

I might agree somewhat with your instructors on that point if life was simple and all shops/home workshops could have access to specifically designed tools. On the surface at first blush it seems sound. But it is flawed - dangerously flawed logic. They need to re-evaluate what they are teaching you. And for God's Sake -- NIK -- please please please do not do that!

It is similar Young Drivers telling a young driving student (I have had 2 take the course), that you must stop at least a car length away from a traffic light in case somebody turns too sharply, and you can then avoid an accident. The problem with that is that it is impractical. What happens if you are the first vehicle at the light, you do as taught by YD and you sit there for ever, because you are 20 feet or so AWAY from the sensor that activates the light...

.

.

There are many things in life that one does because that is the way to do it.

I did a bit of searching and remembering that Shop Notes actually does stuff like this. I went looking, and poof, here is an article on how to safely do exactly that.. cut a slot in PVC piping on Table Saw safely. This is published, so the liability issue is taken care of I imagine. Right click on the link and choose save as, as it is a pdf file Mobile Planer Stand.

As for the circular saw suggestion.. that is the most scary thought going. That is the most dangerous use of a skill saw that I have ever heard. Your instructor needs to take a safety course. Been there, done that.. improvisation can get somebody seriously hurt.... ask my neighbour Bernie G. who has been a carpenter for almost 40 years himself. 5 years ago he improvised and used a circular/skill saw instead of taking the time to setup properly on his portable table saw and

promptly cut off 2 fingers.

promptly cut off 2 fingers.

It was in the newspapers.. cops were out looking for a missing body. Some woman found his finger in her back yard.. 50 feet and across a 6 foot high fence from where he was working. Kind of embarassing for the cops when they figured it all out, but not as embarassing as it was for Bernie or less painful. He still works at his trade, but they were not able to save either finger....

Use the right tool, the right jigs, clamps, hold downs required to perform the needed operation safely. I have seen way too many of my carpenter friends and cabinet maker friends cutting off important parts of their body. After 52 years of life, I still have all of my parts.. well pretty much intact after over 40 + years playing with hand and power tools.

Ask your instructors how to cut a cove moulding on a table saw, dowels, cabriole legs, ? Or a myriad of other tasks that in our so-called intelligent society we now have machines to do so with. I am trying to figure out how many home owners can afford nevermind understand how to use a stick moulder

Confusion breeds Discussion which breeds Knowledge which breeds Confidence which breeds Friendship

- cowboy

- 10+ Years

- Posts: 3414

- Joined: Sat May 15, 2004 11:10 am

- Zip Code: 49229

- Location: MI, Britton

Hmm sometimes I wonder how I made it to 40 with the crazy stunts I have pulled.

Talking about accidents. We had somone experenced putting in a drop ceiling in the basement for my dad when I was a kid and he cut off his thumb with a circular saw.

Rudi I am not a wood wood worker. And I am running this by you as a What if you used a router table with the right bit to do the job in one pass. Clamped on a top limit and side limit bords. Ran it half way in by hand then pulled it the from the back the rest of the way

What if you used a router table with the right bit to do the job in one pass. Clamped on a top limit and side limit bords. Ran it half way in by hand then pulled it the from the back the rest of the way  Perhaps putting a line across the top for indexing

Perhaps putting a line across the top for indexing  I am throwing this out for somone to comment on as I have no idea if this would be safer.

I am throwing this out for somone to comment on as I have no idea if this would be safer.

Billy

Talking about accidents. We had somone experenced putting in a drop ceiling in the basement for my dad when I was a kid and he cut off his thumb with a circular saw.

Rudi I am not a wood wood worker. And I am running this by you as a

Billy

Take care of your equipment and it will take care of you. 1964 cub. Farmall 100 and 130.

"Those that say it can’t be done should not interrupt the ones who are doing it.”

"Those that say it can’t be done should not interrupt the ones who are doing it.”

- Rudi

- Cub Pro

- Posts: 28706

- Joined: Sun Feb 02, 2003 8:37 pm

- Zip Code: E1A7J3

- Skype Name: R.H. "Rudi" Saueracker, SSM

- Tractors Owned: 1947 Cub "Granny"

1948 Cub "Ellie-Mae"

1968 Cub Lo-Boy

Dad's Putt-Putt

IH 129 CC

McCormick 100 Manure Spreader

McCormick 100-H Manure Spreader

Post Hole Digger

M-H #1 Potato Digger - Circle of Safety: Y

- Twitter ID: Rudi Saueracker, SSM

- Location: NB Dieppe, Canada

- Contact:

Billy:

Using a router table would not be my idea of a safer way to do it, and definitely not feeding 50% in then pulling back and reversing or even pulling the stock through to finish.. that is dangerous.. very dangerous and a bad habit to get into. - DON'T ASK

- DON'T ASK

If you do decide to use a router table equip it with a double flute straight bit - 1/4" shank, preferrably a 1/2" shank if you router can handle it would be ok. The double fluted bit will reduce the possibility of the bit grabbing and firing the PVC like a high speed projectile into something permeable like your skin...

Again, ensure that the bit just clears the interior wall of the PVC minimizing the dangers.

Again, ensure that the bit just clears the interior wall of the PVC minimizing the dangers.

The best way as far as I am concerned, and of course as in anything this is just my opinion, the safest machine to do this on is the table saw. A table saw, by virtue of the wording -- a table mounted saw blade - is the most stable machine to do this kind of machining on. The Table Saw has been a staple in Cabinet and Furniture shops since the begining of the Industrial Revolution, and as it has evolved, the techniques, jigs, safety features have all matured to the point where it is one of the safest pieces of equipment available to the home hobbyist, never mind the professional. In the hands of a pro (either home or industry based), awesome functions can be performed safely, effectively, efficiently and in large volumes that were once just pipe dreams.

If you use featherboards and proper hold downs etc., on the router table then you should be ok, just feed at a safe speed.. not too slow not too fast.

Also, the best safety device one can equip a shop with is precisely what is between one's ears. If it doesn't feel safe - IT ISN'T :!:

Using a router table would not be my idea of a safer way to do it, and definitely not feeding 50% in then pulling back and reversing or even pulling the stock through to finish.. that is dangerous.. very dangerous and a bad habit to get into.

- DON'T ASK

- DON'T ASK If you do decide to use a router table equip it with a double flute straight bit - 1/4" shank, preferrably a 1/2" shank if you router can handle it would be ok. The double fluted bit will reduce the possibility of the bit grabbing and firing the PVC like a high speed projectile into something permeable like your skin...

The best way as far as I am concerned, and of course as in anything this is just my opinion, the safest machine to do this on is the table saw. A table saw, by virtue of the wording -- a table mounted saw blade - is the most stable machine to do this kind of machining on. The Table Saw has been a staple in Cabinet and Furniture shops since the begining of the Industrial Revolution, and as it has evolved, the techniques, jigs, safety features have all matured to the point where it is one of the safest pieces of equipment available to the home hobbyist, never mind the professional. In the hands of a pro (either home or industry based), awesome functions can be performed safely, effectively, efficiently and in large volumes that were once just pipe dreams.

If you use featherboards and proper hold downs etc., on the router table then you should be ok, just feed at a safe speed.. not too slow not too fast.

Also, the best safety device one can equip a shop with is precisely what is between one's ears. If it doesn't feel safe - IT ISN'T :!:

Confusion breeds Discussion which breeds Knowledge which breeds Confidence which breeds Friendship

- kinelbor

- 10+ Years

- Posts: 1132

- Joined: Sun May 29, 2005 1:21 pm

- Zip Code: 04762

- Location: ME, New Sweden

- Contact:

The book said no round dowels, I spose with PVC when the pipe rolled it might not bind as hard and throw it. I disagree with the tablesaw being the "safest" way possible, if one was worried about running it through a tablesaw, I would make a line, clamp it, and run down it with a sawzall.

Nik - 1948 Farmall Cub

-

wvpolekat

- 10+ Years

- Posts: 72

- Joined: Wed Nov 22, 2006 2:03 pm

- Location: WV, Buckhannon

- Contact:

Now, I ain't no woodworker, but Nik's idea is not as dangerous as you are making it sound, Rudi. If you build a jig the same thickness as the pipe as Nik stated, your hands would be nowhere near the blade and you could run right down the length of it with a circular saw or router with no danger whatsoever.

The pipe would need to be secured into the jig somehow to keep it from getting thrown out, but thats easy as a couple of screws.

Now, if you thought Nik meant trying to hold it on the bench or something, yes, you are right.

I would even go as far as saying that Nik's method with a jig the pipe fit into would be worlds safer than a table saw. With this method, you would have zero chance of getting cut since your hands are on the saw and not pushing the work across the table.

The pipe would need to be secured into the jig somehow to keep it from getting thrown out, but thats easy as a couple of screws.

Now, if you thought Nik meant trying to hold it on the bench or something, yes, you are right.

I would even go as far as saying that Nik's method with a jig the pipe fit into would be worlds safer than a table saw. With this method, you would have zero chance of getting cut since your hands are on the saw and not pushing the work across the table.

49 Super A (Tinker) 47 Ford 2N (Cricket)

----------------------------------------------------------

If at first you don't succeed, get a bigger hammer.

----------------------------------------------------------

If at first you don't succeed, get a bigger hammer.

- cowboy

- 10+ Years

- Posts: 3414

- Joined: Sat May 15, 2004 11:10 am

- Zip Code: 49229

- Location: MI, Britton

Thanks Rudi

Now I see if you would twist it one way it would pull in harder the other way it would through it back at you.

My thought was at trying to make it a one shot opperation. As it is somwhat rigid for the first pass. After that their is much more of a chance of pinching a blade while trying to hold the pice of material. Perhaps a dato blade (I am thinking of the one you can widen out and make the cut in one pass but I may have the wrong name for it)

I am a metal worker not a wood worker. So mabe one could clamp it down and grind a slot through it with a body grinder. On plastic it will tend to melt its way through but it may work. Might be hard to get it strait though.

Billy

Now I see if you would twist it one way it would pull in harder the other way it would through it back at you.

My thought was at trying to make it a one shot opperation. As it is somwhat rigid for the first pass. After that their is much more of a chance of pinching a blade while trying to hold the pice of material. Perhaps a dato blade (I am thinking of the one you can widen out and make the cut in one pass but I may have the wrong name for it)

I am a metal worker not a wood worker. So mabe one could clamp it down and grind a slot through it with a body grinder. On plastic it will tend to melt its way through but it may work. Might be hard to get it strait though.

Billy

Take care of your equipment and it will take care of you. 1964 cub. Farmall 100 and 130.

"Those that say it can’t be done should not interrupt the ones who are doing it.”

"Those that say it can’t be done should not interrupt the ones who are doing it.”

- kinelbor

- 10+ Years

- Posts: 1132

- Joined: Sun May 29, 2005 1:21 pm

- Zip Code: 04762

- Location: ME, New Sweden

- Contact:

- FuryIII

- 10+ Years

- Posts: 120

- Joined: Tue Jan 09, 2007 6:46 pm

- Location: Tx, Douglass

- Contact:

- Bill Hudson

- Team Cub

- Posts: 9522

- Joined: Wed Jul 26, 2006 10:50 am

- Zip Code: 44057

- Tractors Owned: 57 F-Cub - Dad & Mom's Cub

77 F-Cub - Red Long Stripe - Circle of Safety: Y

- Location: OH, Madison

-

Davesaver

- 10+ Years

- Posts: 189

- Joined: Mon Aug 15, 2005 12:00 pm

One thing to consider with clamping and cutting a loose piece of PVC between two boards with a circular saw as soon as you cut it the potential for slack or give could exist when making your second cut. Or even the first one. If you were to drill an over sized hole in three or four places in one side of the PVC pipe to clearance a screw and a screw driver you can secure the other side of the pipe to a 2x2 or what ever as a carrier. Make it longer than the pipe for a circular saw so when you clamp it, your saw won't run into your clamps. Use a second board to keep the saw stable. On a table saw you can use your standard push sticks and feather boards and just bump your fence if you need to make a wider slot. I have used a jig saw as well again having it anchored to a carrier makes all the difference you can make your carrier a little taller to allow for the stroke of the blade again using two boards to keep the saw stable. The PVC isn't going anywhere.

DaveL

DaveL

Dave Saver ? Because I save everything. Just ask my wife.

-

Mike's 49 Cub

- 10+ Years

- Posts: 148

- Joined: Wed Jul 27, 2005 8:27 pm

- Zip Code: 46970

- Tractors Owned: 1949 Cub 1940 H

- Location: In. Peru

My thoughts. Make a box that has five sides, make it a snug fit. Lay it on top of the PVC pipe, Now take a few 1 1/4 drywall screws and screw the PVC pipe from on top. Raise the saw blade just enough to cut thru the PVC pipe. Make your first cut, shut the table saw off and when it comes to a stop move your box back , remove screws and reposition the pipe for the second cut. Screw the pipe to the box again in different locations and make your second cut. Shut off the table saw again and when it has come to a stop then move the box back and remove your screws and remove your PVC pipe. Safety, Safety, Safety !!!! It would be hard to screw nuts on your Cub with stubs ! I don't think they would work as well as finger tips. Any time your cutting something round length wise -- be careful! I like this method because the PVC pipe is enclosed inside the box , screwed down and your pushing a flat box and shouldn't have to worry about anything moving to cause an accident. My 2 cents worth.

Mike's 49 Cub

-

Mike's 49 Cub

- 10+ Years

- Posts: 148

- Joined: Wed Jul 27, 2005 8:27 pm

- Zip Code: 46970

- Tractors Owned: 1949 Cub 1940 H

- Location: In. Peru

Who is online

Users browsing this forum: No registered users and 47 guests