This site uses cookies to maintain login information on FarmallCub.Com. Click the X in the banner upper right corner to close this notice. For more information on our privacy policy, visit this link: Privacy Policy

NEW REGISTERED MEMBERS: Be sure to check your SPAM/JUNK folders for the activation email.

PTO Pwered Generator?

Forum rules

Notice: For sale and wanted posts are not allowed in this forum. Please use our free classifieds or one of our site sponsors for your tractor and parts needs.

Notice: For sale and wanted posts are not allowed in this forum. Please use our free classifieds or one of our site sponsors for your tractor and parts needs.

-

cubguy's dad

- 10+ Years

- Posts: 556

- Joined: Sun Jan 04, 2009 5:41 pm

- Zip Code: 49265

- Tractors Owned: 1938 John Deere A

(owned 38 years)

1953 Cub

(owned 21 Years)

1963 Olds Cutlass

1970 Ford F-350

(Cub Hauler) - Location: MI Onsted

Re: PTO Pwered Generator?

Great find and project,

Excellent advice already given, I think the Cub would power it just fine. As stated earlier I would not plan to use for hours on end, but for ready remote power and small jobs it should work just fine. The 3,000 watts of power available will limit you to what you can power up.

Very interesting, Keep us posted

Mark

Excellent advice already given, I think the Cub would power it just fine. As stated earlier I would not plan to use for hours on end, but for ready remote power and small jobs it should work just fine. The 3,000 watts of power available will limit you to what you can power up.

Very interesting, Keep us posted

Mark

Experiance is knowing what NOT to do the next time.......

1937 John Deere A (Big John)

1953 Farmall Cub (LiL Red)

Lots of projects.

1937 John Deere A (Big John)

1953 Farmall Cub (LiL Red)

Lots of projects.

- Buzzard Wing

- Cub Pro

- Posts: 10540

- Joined: Mon Aug 09, 2004 10:14 pm

- Zip Code: 02840

- Location: RI, Newport

Re: PTO Pwered Generator?

Nice looking generator (alternator) setup. Looks like the 'input' pulley is keyed, so you should be able to match it up if you need. Probably need a right angle pulley for the PTO output??

If the PTO bearing becomes a problem, should be able to swap it out for a sealed one and never give it another thought. It's a 6205 (?) and very common.

If the PTO bearing becomes a problem, should be able to swap it out for a sealed one and never give it another thought. It's a 6205 (?) and very common.

1971 Cub (Rufus) 1950 Cub (Cathy) 1965 Lo Boy Fast Hitch (Nameless III) 1970 Cub 1000 Loader & Fast Hitch (Lee)

- John *.?-!.* cub owner

- Cub Pro

- Posts: 23701

- Joined: Sun Feb 02, 2003 2:09 pm

- Zip Code: 63664

- Tractors Owned: 47, 48, 49 cub plus Wagner loader & other attachments. 41 Farmall H.

- Location: Mo, Potosi

Re: PTO Pwered Generator?

One thing to remember when powering a generator with a cub or any old tractor is that the governors at best were not real stable and varied widely both in rpm and response time with loads, and wear makes it worse. Running power tools, etc. should be no problem, but anything the requires a stable frequency or voltage may be a problem, not just in failure to work properly, but also in damage to item.

If you are not part of the solution,

you are part of the problem!!!

you are part of the problem!!!

- Bus Driver

- 10+ Years

- Posts: 2917

- Joined: Sat Feb 11, 2006 5:26 pm

- Location: NC

Re: PTO Pwered Generator?

The output frequency of that generator, expressed in Hz, is directly related to the rotational speed of the generator. Voltage will vary depending on the load. Assuming for the moment that the Hz remains constant regardless of the load, as the load increases, the voltage will drop at least slightly. Constant Hz is, for some applications, more important than is constant voltage. So setting engine speed by the voltmeter may not be the best choice. Frequency meters are not expensive these days and are offered by several sellers on eBay.

Luck favors those who are prepared

- bob in CT

- Team Cub Mentor

- Posts: 6018

- Joined: Thu Jun 07, 2007 9:34 am

- Zip Code: 06040

- Tractors Owned: 77 Cub (red); 74 Cub; 52 Cub; 50 Cub ( post-demo)

- Circle of Safety: Y

- Location: CT, Manchester

Re: PTO Pwered Generator?

I can relate to the frequency issue. I had a small generator but after Hurricane Gloria when I had no water for 5 days, I bought a 5000 watt 220V generator by Yamaha and wired in a transfer switch so i could run my water pump. It worked, but things were "funny". lights were different and the pump sounded different. I was pretty careful to shut down phantom loads and manage the refrigerator use to keep within the output range of the generator, especially when starting the water pump. Some years later, it was useful for me to have an amp clamp for work so I bought the full package with frequency measurement to check out the generator and confirm my suspicions. Yep, the unit put out 50hz and that was why motors were turning slow. I suspect I was sold a gray market unit by the dealer that is now long out of business. Fortunately I don't need it that often and all modern electronic devices are rated for 50/60 hz. The motors just turn a little slower.

-

Matt Kirsch

- 10+ Years

- Posts: 4948

- Joined: Tue Jun 08, 2004 3:04 pm

- Zip Code: 14559

- Circle of Safety: Y

- Location: Rochester, NY

Re: PTO Pwered Generator?

Say, if you're concerned about lubrication when running a generator for long hours, why not jack up a wheel and leave the tractor in gear?

-

BigBill

- 10+ Years

- Posts: 7388

- Joined: Sat Jul 22, 2006 5:02 pm

- Zip Code: 00000

- Location: in northern usa

Re: PTO Pwered Generator?

If its not exactly right on the rpms anything without brushes can burn up you need to make sure you have the correct 3,600 rpm. Power tools with brushes are more tollerable.

I'm technically misunderstood at times i guess its been this way my whole life so why should it change now.

-

Like-em-all

- 10+ Years

- Posts: 279

- Joined: Sun Dec 07, 2008 6:03 pm

- Zip Code: 30134

- Tractors Owned: 1948 Farmall Cub

1953 Farmall Super A

1952 Ford 8N

1958 John Deere 320S

1958 John Deere 420S

2008 John Deere 3005 - Location: GA, Douglasville

Re: PTO Pwered Generator?

A lot of knowledgeable advice on things to be considered has been presented here. Lets see if we can summarize:

The Cub's horsepower is deemed sufficient and

IF the Cub PTO pulley size for proper alternator/gnerator RPM is determined and installed,

IF the alternator/generator pulley and the Cub PTO are directionally compatible,

IF the Cub PTO transmission bearings are changed to sealed, permanently lubricated type,

IF a frequency meter is installed,

IF the Cub throttle notch problem in obtaining desired RPM is resolved,

IF the electrical load is maintained within the 3000 Watts available,

IF an operator is present to adjust the throttle to maintain RPM/frequency/voltage due to changes in electrical loads,

then "all systems are a go":D . Does that cover it?

Bill

The Cub's horsepower is deemed sufficient and

IF the Cub PTO pulley size for proper alternator/gnerator RPM is determined and installed,

IF the alternator/generator pulley and the Cub PTO are directionally compatible,

IF the Cub PTO transmission bearings are changed to sealed, permanently lubricated type,

IF a frequency meter is installed,

IF the Cub throttle notch problem in obtaining desired RPM is resolved,

IF the electrical load is maintained within the 3000 Watts available,

IF an operator is present to adjust the throttle to maintain RPM/frequency/voltage due to changes in electrical loads,

then "all systems are a go":D . Does that cover it?

Bill

"One Cub leads to another..." -- old International Harvester proverb.

- Bus Driver

- 10+ Years

- Posts: 2917

- Joined: Sat Feb 11, 2006 5:26 pm

- Location: NC

Re: PTO Pwered Generator?

As already stated, AC generators are actually alternators. Often alternators are not sensitive to direction of rotation. It pays to verify that with any particular unit. For Bob in CT, correcting the frequency problem would be a matter of speeding up the generator- EXCEPT- the voltage would then be much too high (see below). Honda makes a line of small premium-priced portable generators that vary the engine speed according to the load. Those use an inverter which converts the input to DC, then electronically creates AC of desired frequency from that DC. The inverters can accept a variety of input voltages and deliver very precise AC of desired voltage and frequency.

After a bit more thought by my thoroughly-aged mind, help for Bob's generator might be relatively easy. Assuming that his generator does not incorporate an inverter or a voltage regulator, improvement might be possible. Inverters are expensive and most portable generators do not have inverters or regulators. It is a given that the output frequency of alternators is directly related to speed. The frequency in Hz is the speed of the alternator divided by 60 (seconds per minute). So a 50Hz alternator is turning 3000 rpm while a 60hZ alternator is turning 3600 rpm. The residential standard for parts of Europe is 220 volts, 50Hz. USA is 120/240, 60HZ. It is best not to exceed 253 volts (126.5 for the lower) for extended periods of time for USA residential electrical equipment. Taking those facts, increasing the speed of a 50 Hz alternator from 3000 rpm to 3400 rpm would bring the Hz to 56.7, closer to 60. Assuming that the voltage increase is directly proportional to the speed increase (this would need to be confirmed for the particular unit), the voltage would rise to 249.3 (124.7) yielding an output rather well suited for most USA household needs. Seems to me that if the alternator is directly engine driven, the engine should tolerate the speed increase quite well.

After a bit more thought by my thoroughly-aged mind, help for Bob's generator might be relatively easy. Assuming that his generator does not incorporate an inverter or a voltage regulator, improvement might be possible. Inverters are expensive and most portable generators do not have inverters or regulators. It is a given that the output frequency of alternators is directly related to speed. The frequency in Hz is the speed of the alternator divided by 60 (seconds per minute). So a 50Hz alternator is turning 3000 rpm while a 60hZ alternator is turning 3600 rpm. The residential standard for parts of Europe is 220 volts, 50Hz. USA is 120/240, 60HZ. It is best not to exceed 253 volts (126.5 for the lower) for extended periods of time for USA residential electrical equipment. Taking those facts, increasing the speed of a 50 Hz alternator from 3000 rpm to 3400 rpm would bring the Hz to 56.7, closer to 60. Assuming that the voltage increase is directly proportional to the speed increase (this would need to be confirmed for the particular unit), the voltage would rise to 249.3 (124.7) yielding an output rather well suited for most USA household needs. Seems to me that if the alternator is directly engine driven, the engine should tolerate the speed increase quite well.

Luck favors those who are prepared

-

Eugene

- Team Cub Mentor

- Posts: 20372

- Joined: Fri Jul 02, 2004 9:52 pm

- Zip Code: 65051

- Circle of Safety: Y

- Location: Mo. Linn

Re: PTO Pwered Generator?

I work for 30 minutes getting a response ready - then find out BusDriver has posted most of the same information.

I lived in Europe (Germany) for 7 years. We operated US made household equipment (110/120 volts, 60 cycles) on step down transformers. Refrigerator, freezers, washers, dryers and cooking appliances worked quite well on the 50 cycle supplied voltage.

If the alternator/generator rotates at or very close to 3600 rpms, you will not have a voltage or frequency problem with most equipment. Clocks will be a problem.

Most alternators are rotation direction immaterial. Might consider using a 8 or 10 hp gasoline engine - Lovejoy (spider) couplings to power the generator head.

I lived in Europe (Germany) for 7 years. We operated US made household equipment (110/120 volts, 60 cycles) on step down transformers. Refrigerator, freezers, washers, dryers and cooking appliances worked quite well on the 50 cycle supplied voltage.

If the alternator/generator rotates at or very close to 3600 rpms, you will not have a voltage or frequency problem with most equipment. Clocks will be a problem.

Most alternators are rotation direction immaterial. Might consider using a 8 or 10 hp gasoline engine - Lovejoy (spider) couplings to power the generator head.

I have an excuse. CRS.

-

MaineDad

- 10+ Years

- Posts: 401

- Joined: Sun Nov 11, 2007 6:10 pm

- Zip Code: 04260

- eBay ID: mainewh

- Tractors Owned: 1952 Farmall Cub

1963 Wheel Horse 753

1996 Wheel Horse 314-8 - Location: New Gloucester, Maine

- Contact:

Re: PTO Pwered Generator?

Thanks guys. What a wealth of knowledge! As some of you know, I am a Wheel Horse guy too, with several to use. These generators hook up to the front of the tractor, like a snow blower does, and uses the pulley from the horizontal shaft engine. However, the Cub and the Cub's drawbar seem a easier place to mount this generator with the proper setup and safety. First off, I need a PTO pulley to run the belt. Are they available in different sizes?

Micah in Maine

1952 Farmall Cub

1952 Farmall Cub

-

Eugene

- Team Cub Mentor

- Posts: 20372

- Joined: Fri Jul 02, 2004 9:52 pm

- Zip Code: 65051

- Circle of Safety: Y

- Location: Mo. Linn

Re: PTO Pwered Generator?

I would use the current PTO pulley - that is if you have a tractor mounted mower. Then change the pulley on the generator head. Probably the cheapest way to go. Rather than finding an appropriate sized pto pulley and having to purchase a conversion sleeve from Cub to standard pto.

It may be that the diameter of a Cub pulley is close enough. Gonna have to take some measurements and do some math.

It may be that the diameter of a Cub pulley is close enough. Gonna have to take some measurements and do some math.

I have an excuse. CRS.

- Dan Robertson

- 10+ Years

- Posts: 311

- Joined: Thu Feb 06, 2003 4:08 pm

- Zip Code: 47421

- eBay ID: gotowin

- Tractors Owned: 55 cub,

74 cub,

Cub Cadet 1515,

Case 580B TLB,

53 Ford Jubilee,

MF 271XE,

JD 3130,

JD gater - Location: Bedford, IN

Re: PTO Pwered Generator?

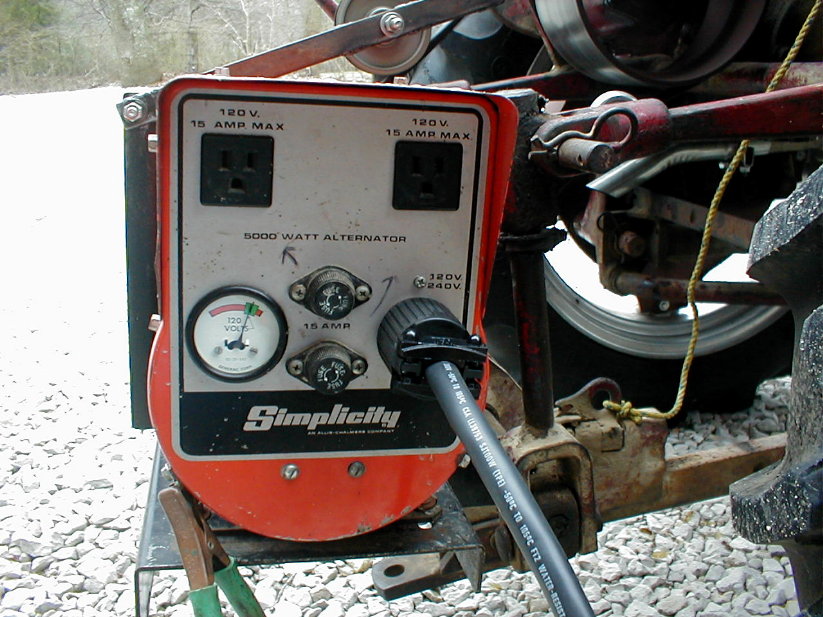

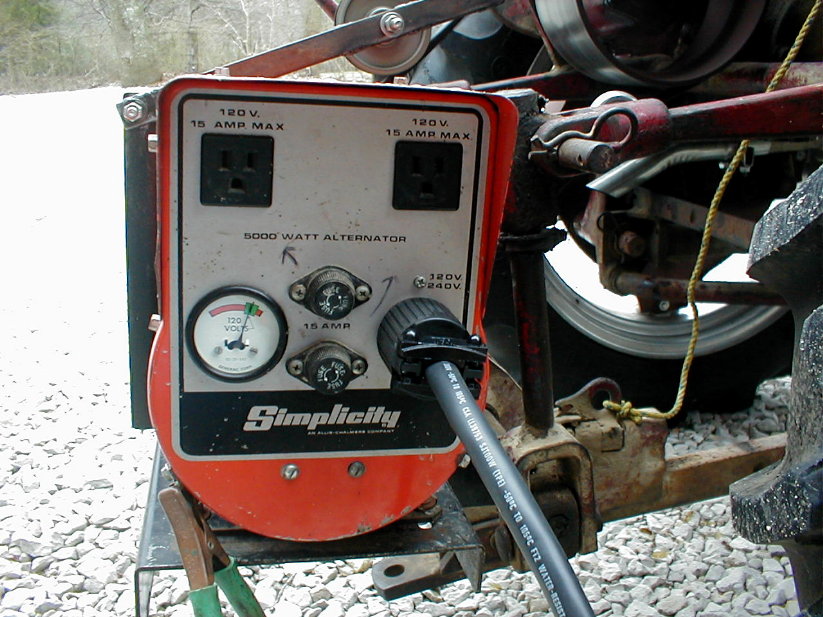

Looks surprisingly similiar to this Simplicity 5 KW that I adapted to the fast hitch on my 55 cub.

The cub runs this unit just fine power wise. I have had a problem on occassion with electronic equipment when connected to it. I think it is a 60 cycle being a little off problem also.

I have since this pic added a 9" v-pulley to the right angle drive.

http://photos.cubfest.com/index.php?cat=10018

The cub runs this unit just fine power wise. I have had a problem on occassion with electronic equipment when connected to it. I think it is a 60 cycle being a little off problem also.

I have since this pic added a 9" v-pulley to the right angle drive.

http://photos.cubfest.com/index.php?cat=10018

I try to keep mine to a minimum

- markwayne

- 10+ Years

- Posts: 271

- Joined: Thu Apr 17, 2008 8:12 pm

- Zip Code: 24550

- Tractors Owned: 1952 F Cub

- Location: VA, Evington

- Contact:

Re: PTO Pwered Generator?

My calibrated eyeball tells me the generator is likely running to fast at WOT, which is where you should run it. If the generator is a 3600 rpm unit (seems to be) and the cub is running 1800 ish (give or take a couple hundred these are not tight fast governors like generators use these days) and the pulley ratio looks to be over 1/2. But electronics that has transformer-less switcher power supplies (most all tv's pc's ect.) don't care much about HZ its the induction motor stuff, like refrigerators that do.

You also need to consider intermittent vs continuous duty. I am betting the cubs hp rating is not continuous duty but a generator can load it up and hold it there like no other load can.

Another thing is the V/F ratio. like 120/60 is normal in these parts. So if you keep the voltage at 120 and drop the HZ motors and transformers heat dissipation increases, some can tolerate this depending on how marginal the design is.

You also need to consider intermittent vs continuous duty. I am betting the cubs hp rating is not continuous duty but a generator can load it up and hold it there like no other load can.

Another thing is the V/F ratio. like 120/60 is normal in these parts. So if you keep the voltage at 120 and drop the HZ motors and transformers heat dissipation increases, some can tolerate this depending on how marginal the design is.

grandpops 52 Fcub #151651, 193 plow, 144 cultivators, 174 runner planter, Type C Duplex hopper, 53 Fertilizer Unit, front/mid mount blade, IH but non Cub 4 foot disc, non IH peg tooth harrow, and one of the infamous and much maligned belt pulleys.

- Dan Robertson

- 10+ Years

- Posts: 311

- Joined: Thu Feb 06, 2003 4:08 pm

- Zip Code: 47421

- eBay ID: gotowin

- Tractors Owned: 55 cub,

74 cub,

Cub Cadet 1515,

Case 580B TLB,

53 Ford Jubilee,

MF 271XE,

JD 3130,

JD gater - Location: Bedford, IN

Re: PTO Pwered Generator?

Micah, I think some may be overly cautious as to run intervals for the cub powered alternator. Of course if your electric power is out for days (as in a hurricane) You would want to move the cub around a little once a day to move the oil up in the tranny. a shot of grease from your gun once a day (same as using the PTO for mowing) in the rear bearing zerk is adequate. The pilot bearing on the PTO is not an issue in this case as both shafts are turning at the same speed. We have run our cub for hours on end with the belt driven cordwood saw and the alternator over the years, and the tranny or PTO have never been apart for any repairs.

I have a 4" pulley on the alternator, and a 9" on the right angle drive, which requires the cub to run at 1600 rpm +/-. This I feel is optimum rpm for horsepower and torgue, and the cub is not sitting there screaming as most one cyl. power plants do. The HZ may not be precise as I have never put a HZ meter on it, but the voltage is pretty centered on the guage.

http://photos.cubfest.com/index.php?cat=10018

I have a 4" pulley on the alternator, and a 9" on the right angle drive, which requires the cub to run at 1600 rpm +/-. This I feel is optimum rpm for horsepower and torgue, and the cub is not sitting there screaming as most one cyl. power plants do. The HZ may not be precise as I have never put a HZ meter on it, but the voltage is pretty centered on the guage.

http://photos.cubfest.com/index.php?cat=10018

I try to keep mine to a minimum

Who is online

Users browsing this forum: No registered users and 26 guests