Page 1 of 2

steel gas line.....practice makes perfect

Posted: Mon Jul 05, 2010 10:38 pm

by John *.?-!.* cub owner

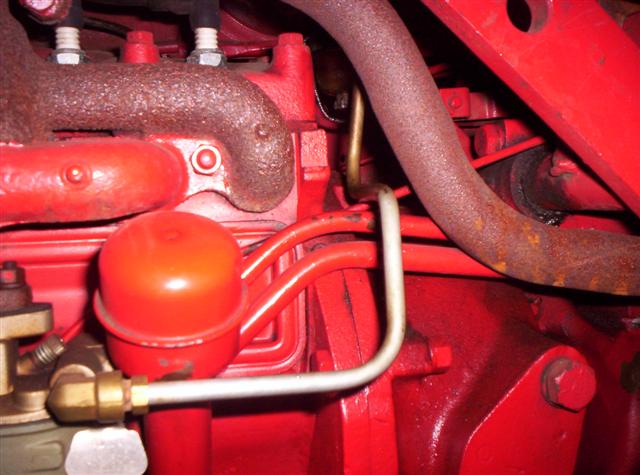

Both of my cubs have Zenith carburetors, one has a short oil fill tube, and the one I just rebuilt has a long one. I wanted to make a fuel line that would pass behind the oil filler, so it would work on both of them, and since the hood was still off Aunt Jessie, I used the 49 for a trial run. Took a couple tries, but this was the result.

Once I got the hood on the 48 I made one like it for her, and was pretty pleased with myself

After a couple hours of running in the shed I ran her up the road, then put the flail on and got some work down. I had been mowing heavy thick grass between 6 and 8 inches tall for a little over an hour when the cub suddenly stalled. It would restart and idle, but the only way it would run faster was to pull the choke about 2/3 way out. No big problem, I figured it was a piece of dirt in the main jet which it was, but while checking it I could hear a bubbling noise, softer and higher pitched than an engine boiling, but otherwise similar. It even sounded as if it were coming from the rear of the engine. After doing some listening and checking I pulled the gas cap (new safety cap), and got a slight whoosh, it was

pressurized. When I looked in the tank i saw bubbles coming up in it. I then loosened the fitting at the carb., and was getting gas and vapor mixed coming out there. The line was clearing the manifold by what I thought was plenty of room, but apparently when i really worked the cub hard on a hot day it was getting enough heat blown back on it from the manifold to boil the gas so hard in it that the vapors were coming out faster than they could escape out the cap vents. Yes, I checked, the vents are open, but as you may have noticed, they are very small. I drove it back to the shed, and cleaned the load jet, which fixed the running problem, then I made one more gas line, staying well away from the manifold.

I went out and mowed for 2 more hours with no more trouble. Apparently the gas line was ok under light duty, but when I put it under a hard load for an extended period it was too close to the manifold. I can see the potential for a real disaster with it pushing fumes out the cap that bad.

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 6:12 am

by Bigdog

John - thanks for the information! It might save someone from a real disaster!

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 6:44 am

by Buzzard Wing

Boiling fuel!?? Yikes. It is pretty difficult to keep the line away from the exhaust with an underslung, surely worth thinking about when installing a line. I wonder if some type of insulation (thinking auto underhood foil stuff??) would help??

If it makes you feel any better EJP, I bet I ruined a whole lot more 5/16" lines than you did. Long dipstick, underslung exhaust, Zenith, but the real trick was it was flared at both ends. Frustrating project! But I see the potential for the same problem.

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 6:50 am

by Mr E

Buzzard Wing wrote:Boiling fuel!?? Yikes. It is pretty difficult to keep the line away from the exhaust with an underslung, surely worth thinking about when installing a line. I wonder if some type of insulation (thinking auto underhood foil stuff??) would help??

If it makes you feel any better EJP, I bet I ruined a whole lot more 5/16" lines than you did. Long dipstick, underslung exhaust, Zenith, but the real trick was it was flared at both ends. Frustrating project! But I see the potential for the same problem.

I have this same issue. If anyone has a solution, please speak up. To date, I have not had a problem, but the potential is definitely there.

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 8:49 am

by John *.?-!.* cub owner

BW, I doubt you will have a problem with your set up. If you look at my original one the gas line is just below and just behind the manifold, including the exhaust leg coming off of the #4 cylinder. With this setup the fan is blowing the heat from the manifold directly onto the gas line. On your under-slung exhaust the gas line is in front of the exhaust pipe, so the fan blows the heat away from the line.

BW, the next time, cut the ends off and use ferrules. They will work with the nuts that come with the lines, and you do not have to work with a fixed length.

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 9:29 am

by ScottyD'sdad

I run the fuel line under the hydraulic lines, next to the bell housing. Keeps it away from the exhaust pipe. No pictures, too computer illiterate, to post them. Ed

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 12:07 pm

by moe1942

Nice line. To prevent problems down the road you might want to remove a section between the tank and carb and use gas approved hose in the middle. Even a short 2" section will prevent work hardening and cracking.

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 1:01 pm

by Rudi

John:

This is a really good thread. Interesting topic and interesting factoids that you discovered. Thanks for posting this as I am sure it may play a part in preventing a serious fire from a similar situation going undiscovered. It needs to be preserved somehow.

Re: steel gas line.....practice makes perfect

Posted: Tue Jul 06, 2010 5:38 pm

by Bill Hudson

John,

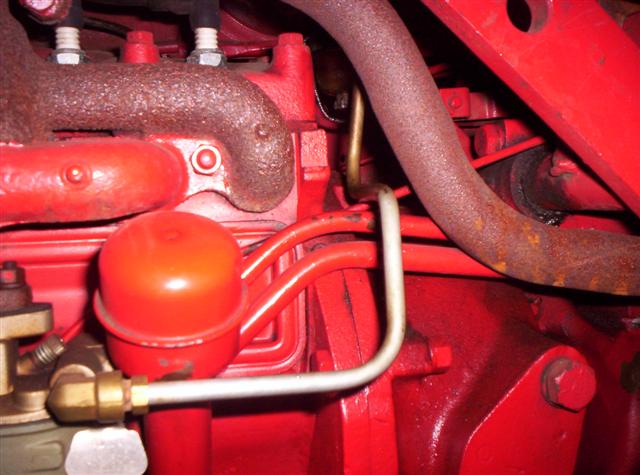

Here is a pic of what used to be on my Cub. Worked it hard plowing with no problems. Like Ed, I've now gone to routing the gas line under the hydraulic lines.

Bill

Re: steel gas line.....practice makes perfect

Posted: Wed Jul 07, 2010 7:51 am

by Buzzard Wing

The flared ends are surely an oddity, never seen it before. I think the Zenith inlet (strainer/elbow) is for a Ford or something, but certainly requires a flared end and same for the aftermarket fuel bowl. Added just another level of complexity to something that was already challenging. The one good thing about a Zenith is you do have some 'horizontal' adjustment.

Cheap tubing benders are available at Lowes and Harbor Freight. For the early Cub I just used the mower pulley on the PTO. I never buy ONE 5/16" line.

Re: steel gas line.....practice makes perfect

Posted: Wed Jul 07, 2010 8:53 am

by challenger

That steel line is neatly bent and likely close to the original installation. For me, however, the flexible rubber fuel line approach with barbs at the sediment bowl and carburetor is the way to go. Though not as original and neat looking, the rubber line easily permits inserting an additional fuel filter into the line, as we discussed in another thread, and you can more easily remove the tank and hood for servicing. If you remove the line at the sediment bowl, all you have to do is hook it up to another barb on your jiffy tank. If the Cub was designed like many tractors of the era with the gas tank and hood separate, I would also go with a steel line.

Re: steel gas line.....practice makes perfect

Posted: Wed Jul 07, 2010 9:19 am

by Hengy

The only problem that I have with "barbs" is that it ruins the threads in both the carb and sediment bowl. Rubber line also scares me in event of a fire on the tractor. Fire will burn through the rubber and will allow the gas to leak out...even bigger fire then. It is relatively easy to put together the regular gas line with steel brake lines, why not do it once and do it right? Temporary tanks are a different story...I make a temporary fitting with a compression ferrule and nut to fit my carb then put the rubber line on that with a hose clamp for temporary use. That way, I don't have to worry about the fuel line...it goes with the hood/tank when I remove that...

Mike in La Crosse, WI

Re: steel gas line.....practice makes perfect

Posted: Wed Jul 07, 2010 12:54 pm

by Rudi

This topic has been discussed often over the last 10 years and the consensus is that the steel line is the safest style of fuel line to use. I have had the rubber lines on all of my Cubs up until this past winter/spring when I upgraded my

Cubs Fuel Systems. I did it this way for a reason. I have already had the gas approved rubber lines fail. They harden, stiffen and crack which is a fire hazard in and of itself. As Mike said, in case of fire from another source, the rubber line will melt rather quickly and then further contribute to a Krispy Kub. Copper fuel lines are not recommended either as they will chafe and break in time from vibration. For safety reasons we do not recommend rubber or copper lines for the fuel system and recommend instead the standard equipment/replacement equipment steel fuel lines.

The hose barbs are NPT and they

will ruin the carb inlet threads for sure as they are NF and not NPT. After having my inlet threads redone, no way am I going to allow a hose barb anywhere near my carbs. Much better seal with the proper threads, ferrules and nuts than with a hose barb, rubber hose and hose clamp. Much safer as well

Re: steel gas line.....practice makes perfect

Posted: Wed Jul 07, 2010 3:37 pm

by challenger

Mike and Rudi,

All good points. The rubber hose was on my Cub when I bought it this spring and it seemed like a better setup to me at first than hard threaded fittings to disconnect and connect, but the safety factor no doubt outweighs the convenience of using a flexible fuel line. This means I will be replacing the rubber line as soon as I can get to it. With regard to the thread issues, I recall when I overhauled the carb that there was a connector/adaptor fitting between the barb and the carb. I took both of these brass fittings apart when I cleaned the carb and never noticed any obvious issues regarding threads or leaks, but maybe the damage had already been done and I just didn't notice. Likewise, I haven't paid enough attention to the barb at the tank to know what the issues may be at the sediment bowl but I did check for leaks after putting my tank on and I have none at present. Thanks again for pointing out the obvious which sometimes just doesn't register until it is too late.

Re: steel gas line.....practice makes perfect

Posted: Wed Jul 07, 2010 3:43 pm

by ToddW

one thing to check, usually the barbs that were put in were over-torqued and /or had different threads than the carb had.

So, doing the steel line upgrade requires a compression ferule and the ability to tighten the fitting. Which is impossible if the barb threads are buggered up

They most always need a helicoil job done on the carb to get things to seal properly.

I have also added the Gary Boutwell "how to" inline hidden fuel filter upgrade to my f-cub.

The steel line/helicoil (Cecil did the Helicoil) and inline hidden filter was one one my best upgrades.