Page 1 of 2

Final thread repair

Posted: Thu Sep 27, 2012 10:09 am

by clodhopper

My rear bolt holes have already been overdrilled and rethreaded to 3/4 by a PO. They are also getting sloppy. I would like to refill these holes and redrill /tap to 5/8x11 tpi which is proper. Now...what I DONT want to do is take it to a shop and have it all welded up. I know there has to be a two part epoxy out there that would be suitable for this. Anyone have any experiences? Thanks!!

Edit: I do plowing/gardening...

Re: Final thread repair

Posted: Thu Sep 27, 2012 10:29 am

by Hengy

Since the finals are cast, you are going to be hard pressed to be able to fill the holes with weld and redrill to the right size. I can't find the thread here, but I do recall someone posted something about full inserts (not helicoils) that went into oversized holes to repair the threads... Let me search and see if I can find them...

Mike in La Crosse, WI (whoops! Gibsonia, PA)

Re: Final thread repair

Posted: Thu Sep 27, 2012 10:34 am

by clodhopper

Hengy wrote:Since the finals are cast, you are going to be hard pressed to be able to fill the holes with weld and redrill to the right size. I can't find the thread here, but I do recall someone posted something about full inserts (not helicoils) that went into oversized holes to repair the threads... Let me search and see if I can find them...

Mike in La Crosse, WI

I will do the same. Thanks Mike!

Re: Final thread repair

Posted: Thu Sep 27, 2012 10:37 am

by Hengy

Here is a website for "EZ Lock" threaded inserts, but it looks like for a 5/8-11 thread, you already have too large a hole for that insert... Maybe someone else has an option...

http://www.catalogds.com/db/service?domain=ezlok&command=locate&category=hvy_crbn_uncMike in Gibsonia, PA

Re: Final thread repair

Posted: Thu Sep 27, 2012 10:40 am

by Former Member

Yes there is a product that works good. I will find the thread and get back to you asap

Re: Final thread repair

Posted: Thu Sep 27, 2012 10:43 am

by Former Member

Here is the thread

viewtopic.php?f=170&t=68694&p=557564&hilit=napa+thread+repair#p557564

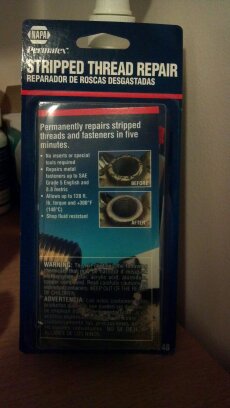

Al, I have had great luck with this. It is Permatex Thread repair kit, part # 765-1248. I get it at NAPA for $13.50

I have repaired final drive bolt holes, carb inlet threads, anywhere the bolt is loose and sloppy. It has held up great in both the finals and carbs.

It withstands chemicals and is good up to 128ft lb of torque.

Make sure you use a clean new bolt, clean the threads in the hole real well, then make sure you use plenty of the release agent on the bolt.

It says wait 5 min before removing bolt, I like to let it sit a couple hours.

Re: Final thread repair

Posted: Thu Sep 27, 2012 11:13 am

by Bus Driver

In my opinion, the bolt holes in the final drives take the hardest beating. I doubt that any repair will take those you describe back to original as good as new.

For the torque tube holes, a couple of mine had been enlarged to 3/4-10. It so happens that the tap drill for 3/4-10 is the same as for the coil insert for 5/8-11. So I simply tapped for the 5/8-11 insert, cleaned insert and hole with lacquer thinner, put JB Weld in the hole, carefully installed the insert (messy process), put more JB inside the insert and let it all cure for 48 hours. Then drilled out the excess JB with standard tap drill for 5/8 -11, tapped with standard 5/8-11 tap for the best possible threads and tightest possible fit for the insert. They have worked well thus far. The torque tube holes are deeper and open on the back, which helps with what I did. With the previous tapping to 3/4- 10 thread, retapping to insert 11 thread results in some areas with very shallow threads, but the starting threads are rather good. For the torque tubes, the boss is large enough to drill and tap for 7/8-9 external thread insert with 5/8-11 internal threads. That is my Plan B should it become necessary.

The shallow blind holes on the final drives do present more of a challenge. Welding would be my plan D, after trying to find replacement finals as Plan C.

I do have one Cub where one of the holes in the final was broken and expertly brazed before my ownership. But the 5/8- 11 was drilled crooked and slightly off pattern. So I built a drilling jig, redrilled for the coil insert and installed it. The hole is now in the correct position and alignment. It has worked well since then. I think that the insert helps spread the stress on the built-up brazing.

Keep all the implement mounting bolts tight. Loose bolts increase the stress on the holes when using implements. Keep a bolt in every hole at all times to help keep the threads clean and keep out insect nests. Use a cordless drill with 3/8 bit at slow speed to clean out packed debris on the bottom of the final drive holes. Let the drill cut the debris, not metal.

Re: Final thread repair

Posted: Thu Sep 27, 2012 12:58 pm

by beaconlight

Bus Driver many post with wisdom but you post with profound wisdom.

Re: Final thread repair

Posted: Thu Sep 27, 2012 7:41 pm

by Bill E Bob

beaconlight wrote:Bus Driver many post with wisdom but you post with profound wisdom.

Re: Final thread repair

Posted: Thu Sep 27, 2012 7:54 pm

by Bob McCarty

Mike, I think you may have misread the EZ lock chart. Internal threads of 5/8" takes an external thread of 7/8" not 3/4". If the 3/4 is already a little wallowed, I'd think enlarging to 7/8 would cut great threads for the the solid insert. Two lengths are available, and I've seen these at Fastenal and other places.

Bob

Re: Final thread repair

Posted: Thu Sep 27, 2012 9:12 pm

by Hengy

Thanks for the correction, Bob! Right you are!!

Mike in Gibsonia, PA

Re: Final thread repair

Posted: Fri Sep 28, 2012 10:25 pm

by clodhopper

Mike,

I also noticed you moved from WI to PA between your first and second post. Do you own a jet?...lol

Re: Final thread repair

Posted: Sat Sep 29, 2012 7:11 am

by Hengy

Haha!! Old habits die hard! My fingers still type La Crosse instinctively when I type my signature line!

Thanks for pointing it out... I'll go fix it!

Mike in La...er...um... Gibsonia, PA

Re: Final thread repair

Posted: Sat Sep 29, 2012 9:13 am

by Denny Clayton

Hengy wrote:Haha!! Old habits die hard! My fingers still type La Crosse instinctively when I type my signature line!

Thanks for pointing it out... I'll go fix it!

Mike in La...er...um... Gibsonia, PA

Why type it? It comes in automatically through the way you have your account set up. Therefore, it shows up twice.

Re: Final thread repair

Posted: Sat Sep 29, 2012 4:20 pm

by Rudi

This is kind of a different solution. Consider the fact that Earl Fauble actually makes drawbar bolts for 3/4"-10NC threads. So, it might be easier to simply redo for the 3/4" size. My wife's uncle - Clorice for some reason had the guys at the university he worked at redrill his finals out to 3/4", when I get his Cub at some point, I will simply have Earl send me a set or two