Page 2 of 2

Re: 54 blade lifting mechanism problem

Posted: Mon Dec 16, 2013 10:59 pm

by Fishman

Thanks for all the replies and the helpfull information. It is a cub and not a loboy. I will install the correct hardened bolt and then go after that mounting plate--much prefered and easier than my idea. I'll post back in a few days with an update. Thanks!

Re: 54 blade lifting mechanism problem

Posted: Tue Dec 17, 2013 5:56 am

by randallc

Welcome to the "posting club". Sounds like everyone has this one figured out. They usually do.

Re: 54 blade lifting mechanism problem

Posted: Wed Dec 18, 2013 8:39 am

by Smokeycub

My blade set up looks like yours and I have no problem but I still use the original bolt. John is correct about a grade 5 at least and the spacing is important. Your bar is allowing the lift arm to move away from the tractor making it easier to bend. I believe the extra bracket Boss mentioned would help too.

Re: 54 blade lifting mechanism problem

Posted: Thu Dec 19, 2013 10:07 am

by david.dickson

A little late in posting this comment, I have just seen this conversation. 1. TM Tractor has the bolt that is needed. 2. While you are there be sure that you have the correct square bushings that go through the support casting. If not, TM has 'em. I just got my rig together, took about a month of beating parts straight, machining bushings and etc. Mine is also a "framkenstien" made of parts of various implements and some creative substutions. The only "creative' part of mine now is the bellcrank extension and lifting rod that I have made until i find the correct parts.

I will post a picture later today after I take some. By the time I finished getting mine together yesterday, it was too dark for good pictures.

-dave

Re: 54 blade lifting mechanism problem

Posted: Thu Dec 19, 2013 3:53 pm

by Don McCombs

david.dickson wrote:While you are there be sure that you have the correct square bushings that go through the support casting. If not, TM has 'em.

There is also an original pair for sale in the Classfied Ads.

Re: 54 blade lifting mechanism problem

Posted: Thu Dec 19, 2013 8:36 pm

by danovercash

While you are at it, get a piece of flat iron 2" or 3" by 9" and drill three holes on center at 1", 4", and 8". You should have two holes one inch on center from each end and one hole 4 inches from one of the end holes. The 4" holes will fit the torque tube and the other end goes to the braces. Just like the parts pictures( number 1, second page).

Re: 54 blade lifting mechanism problem

Posted: Fri Dec 20, 2013 5:06 pm

by Fishman

Update: I found a grade 8 bolt at the local case dealership and have it snug--I feel some drag when I move the lifting arm by hand and the bolt turns with the arm. I will keep an eye on it once I fire it up

As for that plate (item #1), I can't have one made anytime soon. However, the " U " shaped brace that hangs from the tractor (where the blade attaches to) looks very perpendicular to the ground. The current plate measures 2 1/2" from center and is also not in line with the 2 mounting bolts, but I think it'll be OK for the short-term.

Thanks again everyone. Let it snow!!

Re: 54 blade lifting mechanism problem

Posted: Fri Dec 20, 2013 5:46 pm

by Bill Hudson

Fishman wrote:Update: I found a grade 8 bolt at the local case dealership and have it snug--I feel some drag when I move the lifting arm by hand and the bolt turns with the arm. I will keep an eye on it once I fire it up

Drag and the bolt turning indicate that the bushing in the pivot point needs to be replaced. The bushing should be a little longer than the arm is wide. Then you can tighten the bolt and the arm will pivot freely because the bushing is tight and the arm isn't.

Bill

Re: 54 blade lifting mechanism problem

Posted: Fri Dec 20, 2013 10:03 pm

by Scrivet

Fishman wrote:........... I will keep an eye on it once I fire it up......

I always put my bolt through with the nut by the lift arm. I can see if it starts coming loose. I don't have the best bushing in my lift arm. I just snug up the nut so it doesn't bind.

Re: 54 blade lifting mechanism problem

Posted: Sat Dec 21, 2013 11:34 am

by Bill Hudson

Scrivet wrote:I always put my bolt through with the nut by the lift arm. I can see if it starts coming loose. I don't have the best bushing in my lift arm. I just snug up the nut so it doesn't bind.

The disadvantage of inserting the bolt this way is that the bushing is on the threads which leads to excessive wear on both the bolt and bushing. Put the bolt thru the other way with a good bushing, tighten the bolt tight and you should be good to go. In several years of pushing a lot of snow, I have not had an issue with this bolt loosening up.

Bill

Re: 54 blade lifting mechanism problem

Posted: Sat Dec 21, 2013 1:38 pm

by John *.?-!.* cub owner

to Bills comment. The bushing should be long enough to reach through the arm with a small amount exposed on each side so the bolt tightens against it, and leaves the arm free to pivot on the bushing. The bushing on mine came from the local ACE hardware, I had to use 2 to get the right length, but it has been that way for several years with no problem.

Re: 54 blade lifting mechanism problem

Posted: Sat Dec 21, 2013 6:22 pm

by Boss Hog

Apiece of black pipe works great as a bushing you can do a search of my post and find pics of replacing the bushing.

Re: 54 blade lifting mechanism problem

Posted: Sat Dec 21, 2013 7:49 pm

by Scrivet

Yep, I need to replace the bushing.

I have always put the bolt in with the nut on the right for several years and do not see any wear nor do I have any problems with it loosening up. I just like it there to see if it does get loose rather than hunting for it in a pile of snow.

I also install it that way because it's easier to tighten.

Oh yeah, another reason is

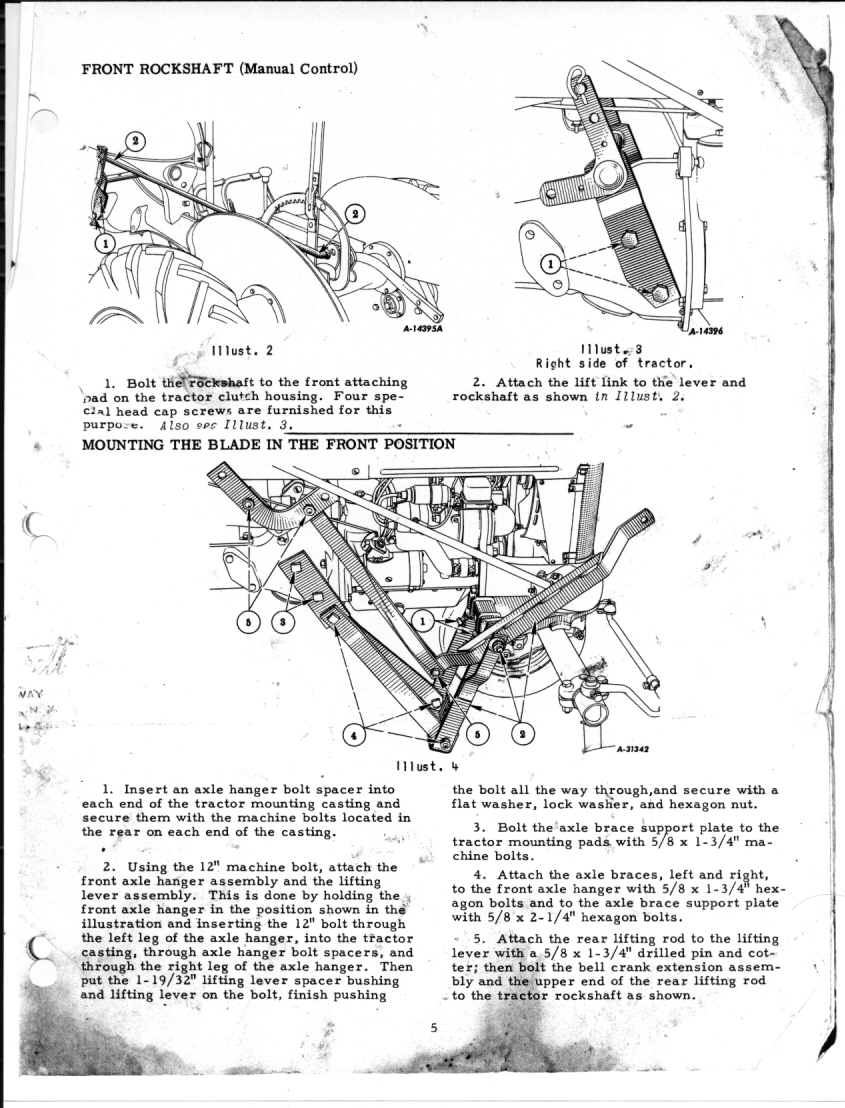

that's the way the manual says to install it. Read #2 and/or look at the other pictures in this manual from Rudi's server. John (I don't know Bill well enough to pick at him to

), that knock at your door will be the Correct Police

- Page 05.jpg (399.93 KiB) Viewed 189 times

Re: 54 blade lifting mechanism problem

Posted: Sat Dec 21, 2013 8:19 pm

by Boss Hog

Scrivet, just shows you that you cant believe everything you read

Re: 54 blade lifting mechanism problem

Posted: Sat Dec 21, 2013 11:00 pm

by John *.?-!.* cub owner

According to the manuals, etc. the bolt on mine is in backwards. I started putting it in that way after a soft bolt bent and I had to pull the bent end out through the blocks in the bolster. Ever since then I have put the bolts with the nuts under the engine, that way if I bend one it is not near as hard to remove. Since I learned to use a harder bolt I have not bent one, but that part of my blade assembly stays on year around, and I do not plan to take it apart to make it correct according to the manual.

to Bills comment. The bushing should be long enough to reach through the arm with a small amount exposed on each side so the bolt tightens against it, and leaves the arm free to pivot on the bushing. The bushing on mine came from the local ACE hardware, I had to use 2 to get the right length, but it has been that way for several years with no problem.

to Bills comment. The bushing should be long enough to reach through the arm with a small amount exposed on each side so the bolt tightens against it, and leaves the arm free to pivot on the bushing. The bushing on mine came from the local ACE hardware, I had to use 2 to get the right length, but it has been that way for several years with no problem.