Page 1 of 3

Power Angle Plow Question

Posted: Mon Dec 30, 2013 1:45 pm

by TCP

Hi Folks,

I'm putting together a power angle set up on my '65 Loboy. Naturally, I have some questions:

First off, I'm thinking of using either the PRINCE HCSVG0002/LS3000 LOG SPLITTER VALVE (PN: 9-1262) or the PRINCE RD-2575-T4-ESA1 DA OC VALVE (PN: 9-6765) valve from Surplus Center. Which valve is the better choice? Personally I'm not crazy about the idea of using a detent valve.

I'm planning on using a 1" cylinder with 1/4" ports and an 8" stroke. Any reason to use a 2" bore cylinder? Any reason not to?

From the reading I've been doing here, I'm wondering if I should add an in-line pressure relief valve to give me the option of setting peak pressure below 1500 psi. Would this be necessary?

And the exhaust runs right up against the TC manifold block. I'm going to have to move the exhaust pipe away to get enough clearance or re-route it. Anyone have any suggestions for this?

I'm sure I'll have more questions as I go, and I'll add some pictures here as I go. Thanks!

Re: Power Angle Plow Question

Posted: Mon Dec 30, 2013 4:20 pm

by ricky racer

The power angle is a great project and a great addition to the Leveling and Grader Blade. I use mine a lot every time I plow snow. Any valve you choose should have an adjustable pressure relief. There is no need for an addition relief inline providing the valve has one. The Cubs hydraulic system only puts out about 1500 psi so the relief should be able to adjust the pressure below that, probably in the 1000 to 1500 psi range. Prior to starting up the tractor after adding the valve into the hydraulic circuit it is a good idea to back out the pressure adjustment to it's lowest setting then bring up the pressure once you see everything is working as it should. Bailey.net is another good source for hyduaulic components.

Regarding the cylinder, the advantage of the 1" cylinder is it will respond quicker to directional changes. In my opinion though, that is the only advantage. Disadvantages are the cylinder will be manufactured as a lighter duty cylinder with a small diameter rod and will be more likely to break. A 2" diameter cylinder will be much more robust. The Leveling & Grader Blade takes a good pounding pushing snow and striking frozen obstacles hidden by the snow.

One thing I would recommend when fabricating the power angle is when you pin the cylinder or rod, drill the holes in the mounting tabs oversized so the cylinder has some movement. The Leveling & Grader Blade will most likely have sloppy in every connection and if you make the cylinder connection to rigid, you might break the cylinder ears off. That's just my 2 cents.

Re: Power Angle Plow Question

Posted: Mon Dec 30, 2013 9:24 pm

by TCP

Nice setup! I think I'll get a 2" cylinder from Fleet Farm, it's less $$ anyway. I picked up a 4 way valve at Northern which has an adjustable relief valve range of 1000-3000 and preset at 1500. That should work I think.

Re: Power Angle Plow Question

Posted: Sat Jan 04, 2014 12:52 am

by glennhuff

I think that you will be happy with the 2" cylinders. I used 1" cylinders, thinking that the hydraulic pump would not put out a lot of volume. As it is, the movement of the cylinders is too fast. It is hard to adjust a small amount. That may not be a big deal for plowing snow, but we don't get a lot of snow here on the Oregon coast, and my blade is used mostly to grade driveways, and scrape the barn floor. Good luck with your project.

glenn

Re: Power Angle Plow Question

Posted: Sat Jan 04, 2014 10:05 am

by John *.?-!.* cub owner

In my area (70 miles south of St. Louis) we very rarely get more than 6 inches of snow on the ground at ay one time, but they are calling for 10 to 12 Sat.-Sun., I may be wishing for a blade extension like yours before this is over.

Around 30 years ago I had a Homelite T15 garden tractor, which was a real brute, unlike what they call garden tractors now. It weighed about 1000 pounds, and I had converted it's belly blade to front use, plus I had loaded the tires with iron ballast (a powdered barite mix) We got so much snow one winter that I ended up getting it crosswise in the road and was ramming the snow banks with the blade to push them back so I could plow more snow out of the road.

I wish I had a power system to control the right left tilt for crowning roads when grading. That would be handier for me than the power angle. It would also be a lot harder to design.

edit, here is a picture of the T15 I found on Michaels Tractors. With the front blade mounted, which only extended about 10 inches out the front I could barely close the tailgate on an 8 foot truck bed when I loaded it. That was probably the best all around lawn garden tractor I have ever seen, I would gladly trade my fancy ZTR for a new one like it.

Re: Power Angle Plow Question

Posted: Mon Jan 06, 2014 2:21 pm

by Dan Robertson

I fixed the exhaust pipe on mine by bending down slightly at the factory bends. This also dropped the muffler slightly requiring me to redo the muffler mount bracket.

If you go to the Farmall Cub photo host website, look in the gallery section, 1st page, down on the left side to Gotowin (my Ebay user name) albums, You can see lots of pics of my hyd. angle install along with the other remote hydraulics installed on this 1955 cub. Another thing to consider when locating the mounting points for the angling cyl. on the front blade is to check that the tire when turned to extremes does not interfere with the cylinder or hoses both when the blade is raised and or lowered.

Re: Power Angle Plow Question

Posted: Mon Jan 06, 2014 4:34 pm

by gusbratz

to make it 4 way you could use and old front hub bearing off of a 4wd truck. pull both pins out of the pitch adjustment and weld the bearing into the center of the back of the blade and bolt it to the front of the angle frame. you would have to ditch the trip spring on the bottom. then add an upright post in the center of the angle frame. install a hyd cyl going out from that post to a bracket on the back of the blade and it would pitch side to side for crowning. that would be sweet.

Re: Power Angle Plow Question

Posted: Mon Jan 06, 2014 11:49 pm

by TCP

Thanks for the info Dan! That's good advice about the tire clearance. I thought about straightening out the offset bend in the pipe where it runs along the hydraulic lines, but the pipe is old, thin, and pitted (probably is original) and I didn't think it would survive that effort. I cut a piece off the muffler tailpipe, cut the offset out, and welded the straight piece in. There was no need to change the muffler mount this way and I should have enough clearance.

[/URL]

Yeah, I know my cub ain't pretty. It lived outdoors until about two years ago.

Re: Power Angle Plow Question

Posted: Sat Jan 11, 2014 3:23 pm

by TCP

So I'm nearly done making the mounting bracket for the valve, these pics are of the first fit-up. I had to move the fender on the outside (wheel side) of the fender mount, and made use of two existing holes in the fender and one of the touch control bracket bolts. I have to adjust it a little, the valve spool housing is 1/4" away from the gas tank (looks like it's touching in the photo but it's not) and that's a little close for my liking.

Re: Power Angle Plow Question

Posted: Sat Jan 11, 2014 3:27 pm

by TCP

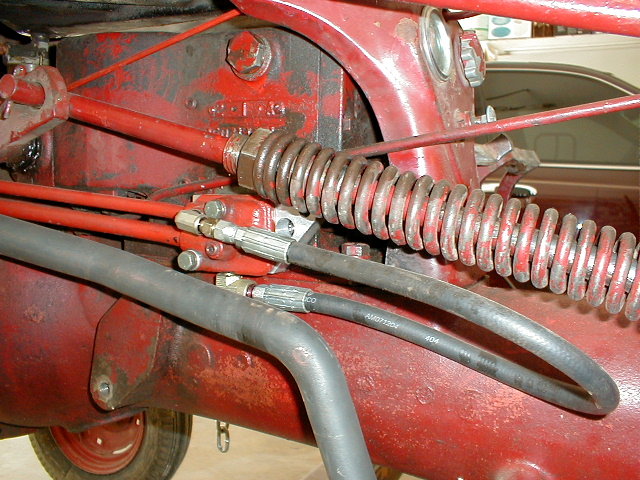

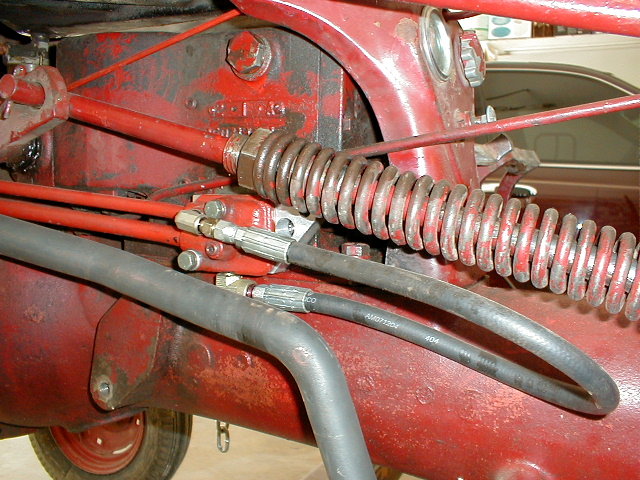

Last night I made the bypass block out of a scrap piece of aluminum at work. That's why there's a drill hole part way through on the near edge. Will that be a problem? I haven't taken the hydraulic lines off the pump and TC unit yet, I'd like to find out if that will be a problem so if it is I can make another one.

Re: Power Angle Plow Question

Posted: Sat Jan 11, 2014 5:49 pm

by ricky racer

Should not be a problem.

Re: Power Angle Plow Question

Posted: Sat Jan 11, 2014 6:13 pm

by TCP

ricky racer wrote:Should not be a problem.

Cool, thanks!

Re: Power Angle Plow Question

Posted: Mon Jan 13, 2014 12:12 am

by TCP

I welded everything together and got the plumbing mostly done today. I just need a few more fittings and different length hoses because I changed my plan for the hydraulics. I used a couple of Category 1 lift arm ball sockets to make rod ends for the cylinder mounts. I used a Cat 1 stabilizer arm for steel stock (less than $10 for a 2" x 1/4" steel bar 32" long - it cost $5 less than a piece of 3/16" in the hardware department) and cut a radius in the end of the bar with a 2-3/8" hole saw and welded the ball sockets to the bar. I had to use a 1" x 1-1/8" x 1" bronze bushing, and grind the ball sockets so they would fit in the cylinder clevises, but this will act as a swivel joint to provide a little flexibility without being loose. This pic shows the cylinder mounts points and cylinder dry fit.

Re: Power Angle Plow Question

Posted: Mon Jan 13, 2014 4:52 am

by ricky racer

Great idea using the ball sockets. It's looking good.

Re: Power Angle Plow Question

Posted: Mon Jan 13, 2014 7:55 am

by ToddW

That looks great! Nice job!!

[/URL]

[/URL]