Sediment bowl testing

Posted: Mon Sep 05, 2011 6:59 pm

I had a hood off and the sediment bowl removed due to damaged threads in the outlet that goes to the carb.

After getting it heli-coiled, I wanted to make sure I had corrected the problem

without going thru all the re-assembly steps [install bowl on tank, reinstall hood, hook up gas line, etc., etc.]...

So I came up with this to test the compression fitting joint while the bowl was still off the tank.

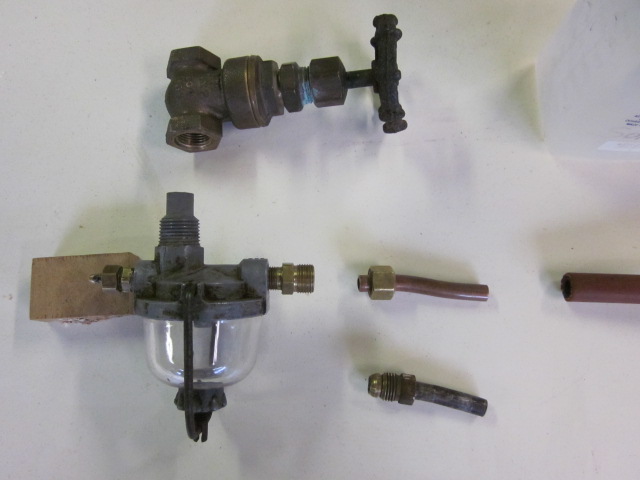

Items needed:

1- Valve with the same threads as those that go into the tank - think they are 3/8" pipe thread.

I used a valve instead of a pipe cap, because it allows me to "bleed" off air so the pressure isn't too high.

2- Short piece of air hose.

3- The appropriate fitting for your connection, on a piece of gas line - typically this will be 1/2-20 thread.

In the photos, I show 2 different ones I have, depending on what I am attaching to on the bowl.

4- Your bottle of soapy water.

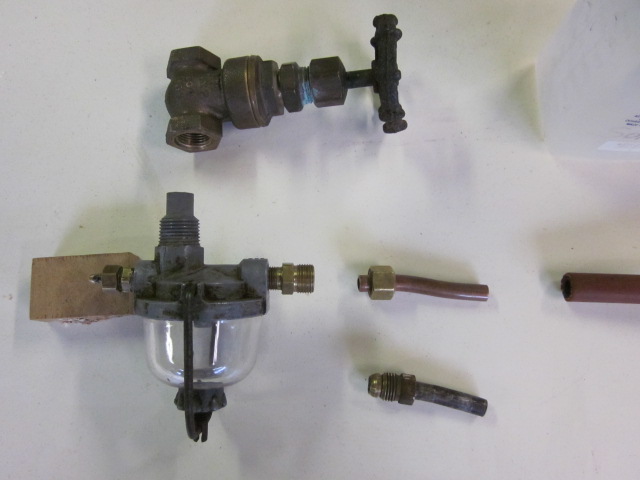

Put the pieces together and give it some air while testing the joint with soapy water.

Don't work about air leakage at your valve or hose joints - we don't want them airtight anyway.

Make sure your gas shutoff is open so air can escape thru the valve.

WARNING: Do NOT use excessive air pressure - damage or injury may result !

I put this together with stuff laying around the house - so cost was $0...

But time saved is PRICELESS !!

photo of an earlier test

After getting it heli-coiled, I wanted to make sure I had corrected the problem

without going thru all the re-assembly steps [install bowl on tank, reinstall hood, hook up gas line, etc., etc.]...

So I came up with this to test the compression fitting joint while the bowl was still off the tank.

Items needed:

1- Valve with the same threads as those that go into the tank - think they are 3/8" pipe thread.

I used a valve instead of a pipe cap, because it allows me to "bleed" off air so the pressure isn't too high.

2- Short piece of air hose.

3- The appropriate fitting for your connection, on a piece of gas line - typically this will be 1/2-20 thread.

In the photos, I show 2 different ones I have, depending on what I am attaching to on the bowl.

4- Your bottle of soapy water.

Put the pieces together and give it some air while testing the joint with soapy water.

Don't work about air leakage at your valve or hose joints - we don't want them airtight anyway.

Make sure your gas shutoff is open so air can escape thru the valve.

WARNING: Do NOT use excessive air pressure - damage or injury may result !

I put this together with stuff laying around the house - so cost was $0...

But time saved is PRICELESS !!

photo of an earlier test