Are you sure about that Mattusing a POWER BEYOND valve, specifically

Thanks,

Rick

Are you sure about that Mattusing a POWER BEYOND valve, specifically

That's says it all. The real reason for the power beyond was designed to strengthen the new remote valve, but by doing so, they needed a way to release the trapped fluid on the opposite side of the working 2 way curcuit. That brings up the question of where the heat is really generated from. If it's all at the pump and you don't have any resrictions elsewhere in the system, you're only gaining some addition cooling when you're using the remote(newly added) valve. When you're not using the remote valve, no fluid passes through the added tank. I know you're probably saying-"if you're not working the remote system, you're not generating any heat and don't need the extra cooling"but won't have any flow if the remote cylinder isn't being used.

Jim Becker wrote:It will work. That is the way IH plumbed the 1000 loader. The manual shows how to connect, but may not be totally clear. You need a bypass block. Pressure from the TC manifold goes to the remote valve inlet. The output from the valve (where flow goes in neutral) goes to the bypass block. The dump from the valve (return flow from the remote cylinder) goes into the top of the auxiliary tank. A line from the bottom of the auxiliary tank goes into the Touch-Control filler. The auxiliary tank (and anything added in series with it) are under low pressure and provide cooling but won't have any flow if the remote cylinder isn't being used.

Rudi wrote:Bill:

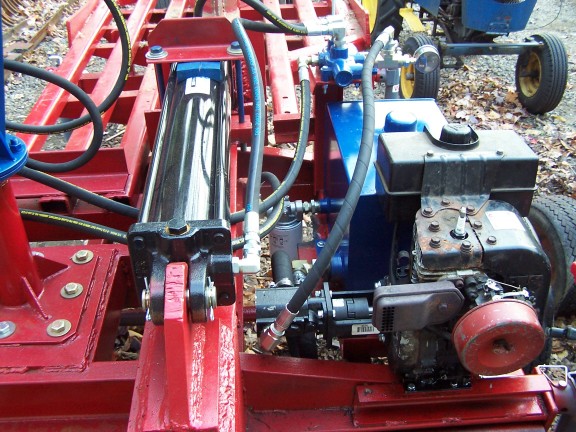

That is some serious log splitter. I am not sure it would be even a good idea to pull that one with a Cub.. especially down a long hill

Nice job.. really nice piece of equipment.

Users browsing this forum: No registered users and 5 guests